2017 / 2018

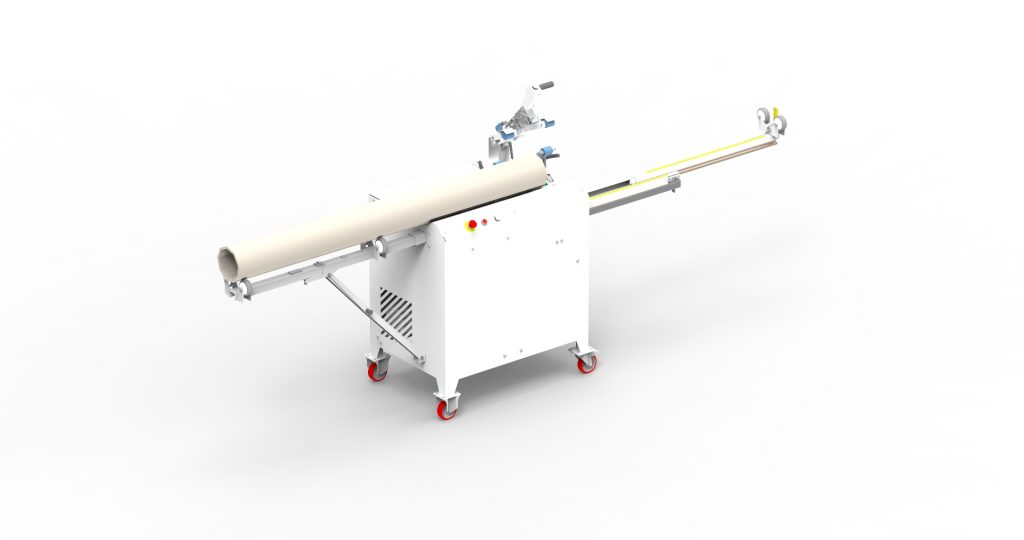

Cutting device for winding roles

Graduation year

Customer

Starlinger & Co. Gesellschaft m.b.H. – viscotec (Standort in St. Martin)

Graduates

Lehmann Philipp

5BHMBA

Stöttner Tobias

5BHMBA

Zauner Elias

5BHMBA

Supervising tutors

Stockinger Thomas

Starlinger Josef

Project description

A machine had to be developed which cuts different roles from a raw length of three meters to a desired length. This was previously time-consuming done manually with the help of a jigsaw, an angle grinder or the band saw available in the factory.

A market analysis was carried out to determine whether similar machines are already exiting and what functions they provide. After that various cutting tests with different cutting tools were carried out and the results were presented. An automated and a purely mechanical concept were then worked out, including a summary of the estimated costs. The company Starlinger viscotec then decided on the mechanical system for cost reasons and the detailed construction started. Special attention was paid to developing a compact and cost-optimized machine.

The cutting device itself consists of a base frame construction made of sheet metal. A support arm is mounted on it, which can be quickly folded in and out. Furthermore, there is an extendable device in the frame, which helps to set the desired length. The role itself is placed on rollers and set in rotation by two drive rollers, which are driven though a belt by a geared motor. The role is additionally secured by two support rollers. If the two-hand operation is activated and the knife arm is moved downwards the motor starts to set the role in rotation as soon as the tension rollers, which are mounted on the knife arm, touch the role. The cut is made by further pressing down the knife arm through a standard Stanley blade.

Benefit:

- clean and glued cutting surface

- no dust generated

- less time consuming

- The machine previously required for the cutting process is now available for other activities during the cutting process.

Technical data:

- Cutting of cardboard roles with diameters from 3 to 8 inches

- raw lengths from 300 to 3000 mm possible

- System with a total length of 4.5 m can be stowed to a length of 1.2 m

- Simple, safe and fast handling

- Price: 4 500,00 €