2020 / 2021

Modernisation of a resin mixing plant for reactors

Graduation year

Customer

Coil Innovation GmbH

Graduates

Hörmann Jonas

5BAT

Mühlböck Daniel

5BAT

Pointner Tobias

5BAT

Supervising tutors

Felhofer Hubert

Project description

Abstract

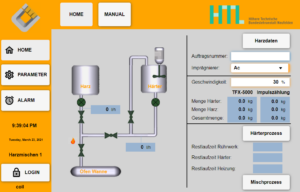

For the production of reactors for electrical substations, the company Coil Innovation GmbH needs a special resin-hardener mixture. A resin mixing plant produces this mixture and pumps it into the tank of the furnace plants. There were two such plants in production, but they no longer met the company’s requirements in terms of both control technology and electricity. Therefore, the plants should be modernised in the course of a diploma thesis.

At the beginning of January 2020, we were familiarised with the task as a project team. The client set the deadline until the end of June 2020 to draw up a circuit diagram, including ordering the components, so that we could assemble our control cabinets and integrate all the components in the summer of 2020 during an internship with the client. Afterwards, we began to create a programme for the system, which we were able to complete in mid-December. At the same time, we also set up a visualisation, which is easy to operate. Thanks to a test setup, the programme could be tested and optimised. The installation and commissioning followed afterwards.

After a short familiarisation phase, we were able to make very quick progress in creating the circuit diagrams. Thanks to the timely sending of the order list to the client, all electrical components could be ordered and delivered in time for the start of the internship. Thereby, the assembly of the cabinet could begin immediately. Due to the quick completion of the two control cabinets, the remaining internship time could be used for getting to know the software for PLC programming. Participating in an online seminar by B&R (Bernecker & Rainer) and receiving training from the client’s employees, we quickly learned how to use the software. The purchaser provided us with motors and valves for a test setup, which helped us a lot in optimising the programme. Due to delays in the delivery of the hardener pump and the flow sensors, the start of commissioning was postponed.

The project was handled smoothly for the most part, only certain work was prolonged due to

COVID-19-related delivery problems with individual components. In general, some work was made more difficult by the pandemic. The project team always enjoyed the full confidence of the client and the school.

Task:

- Control system conversion to Bernecker & Rainer

- Creation of a clear visualisation

- Program creation with Automation Studio

- Circuit diagram creation with WSCAD

- Setting up a control cabinet with WSCAD Cabinet

- Setting up the frequency inverters with Lenze Easy Starter

- Construction of the control cabinets and wiring of the mixing units