2011 /2012

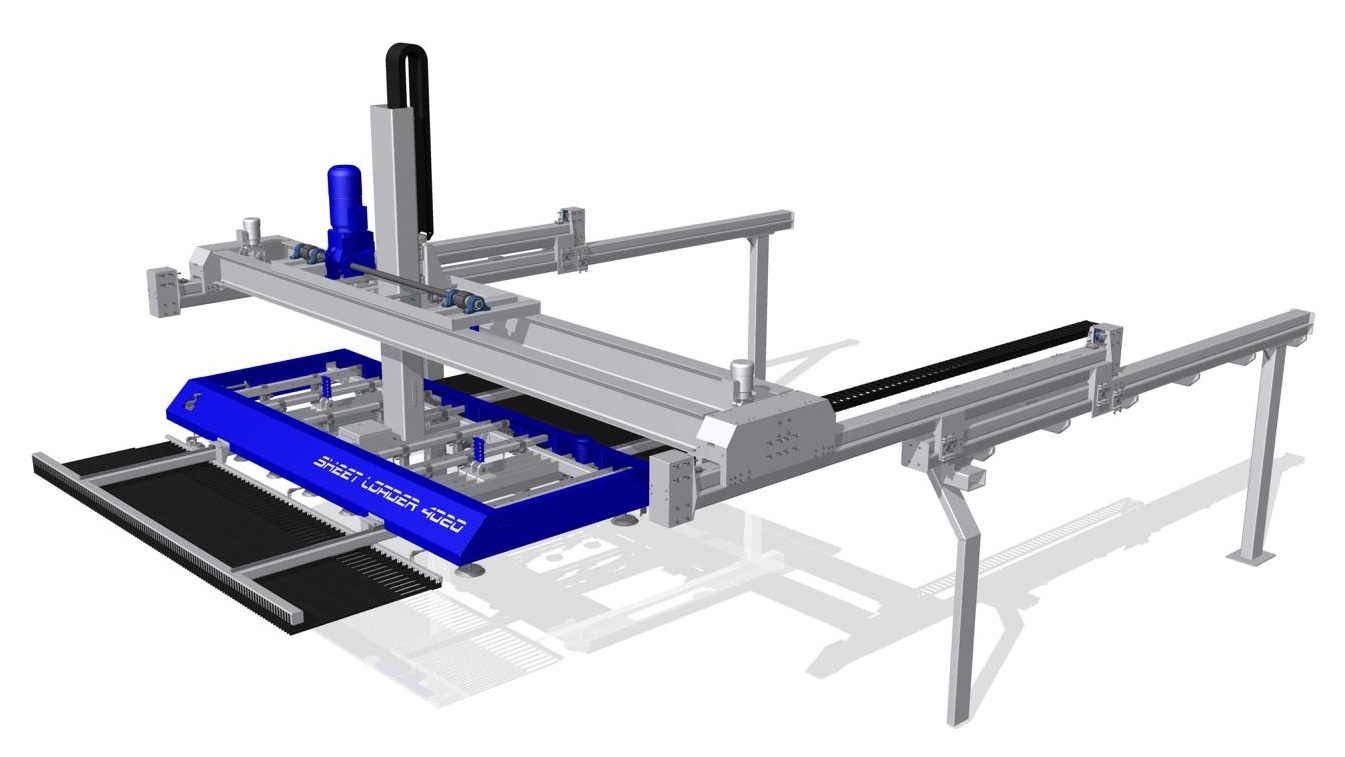

Sheet Loader 4020

Graduation year

Customer

Fa. Stoiber GmbH

Graduates

Mahringer Ulrich

5BAT

Paster Georg

5BAT

Radler Andreas

5BAT

Roth Stefan

5BAT

Stoiber Manuel

5BAT

Winkler Philipp

5BAT

Supervising tutor

Wurm Johannes

Problem description

Our customer Stoiber Ltd. has 29 employees and specialises in innovative automation ideas.

The production of the required metal parts usually takes place on a laser cutting machine; TruLaser 3040.

The sheet metal has to be manually positioned and removed from the laser table. This requires the presence of an employee, which severely restricts the productivity of the laser cutter.

Objective

The HTBLA Neufelden was contacted by Stoiber Ltd. whom requested a fully automated solution to loading and unloading the laser cutting table.

The following points were to be considered from the outset of the project:

- Modelling, planning and preparation of mechanical and control units should be kept simple and space-saving was a priority.

- The safety of the entire system should be guaranteed during installation and commissioning.

- Integration of control components in the existing PLC of the material storage and designing a user-friendly control visualisation

- The creation of appropriate interfaces to enable data exchange between the laser cutter, the material storage and the company PLC; via Profibus

- Designing the necessary Profibus network

Final solution

The final design was manufactured by the customer, Stoiber Ltd and installed in the production hall.

It has been in operation since the end of May 2012.

The laser cutter can now be fully, semi-automatically or manually loaded and unloaded.

System description

The raw material, sheet metal, is supplied as required by signals sent from the loader to the storage area.

The sheet metal is lifted, from the supply palette by suction cups and positioned on the cutting table over which the interchangeable laser cutter operates.

After the laser has completed the cutting operation, the loading mechanism removes the sheet with the aid of rakes – which engage between the cutting grate.

The cut blank can then be placed on a separate palette.

Thanks to the fully automated process, it is now theoretically possible for the laser cutter to operate 24 hours a day and 365 days a year, without the company having to employ additional staff.